When it comes to electric vehicles, the most important thing is battery tech. EVs wouldn’t exist with batteries. What is needed now, mostly, is faster charging and increased capacity. Everyone’s working on both, but it’s just possible that capacity is about to get a shot in the arm.

Researchers at the University of Michigan have come up with a new type of battery. It uses a new bio-membrane derived from Kevlar to create new lithium-sulphur (Li-S) EV batteries with a vastly increased capacity. And, as we all know, capacity equals range.

Building better batteries

So what’s the big deal with a Li-S battery? Its possible capacity, for starters. A standard lithium-ion battery has a max capacity of 300Wh/kg. Li-S, at least theoretically, has an energy capacity of 2,510Wh/kg. That’s a huge jump in potential capacity without increasing weight. These power banks could also work out to be cheaper since they utilise sulphur instead of cobalt. Sulphur is a little easier to get.

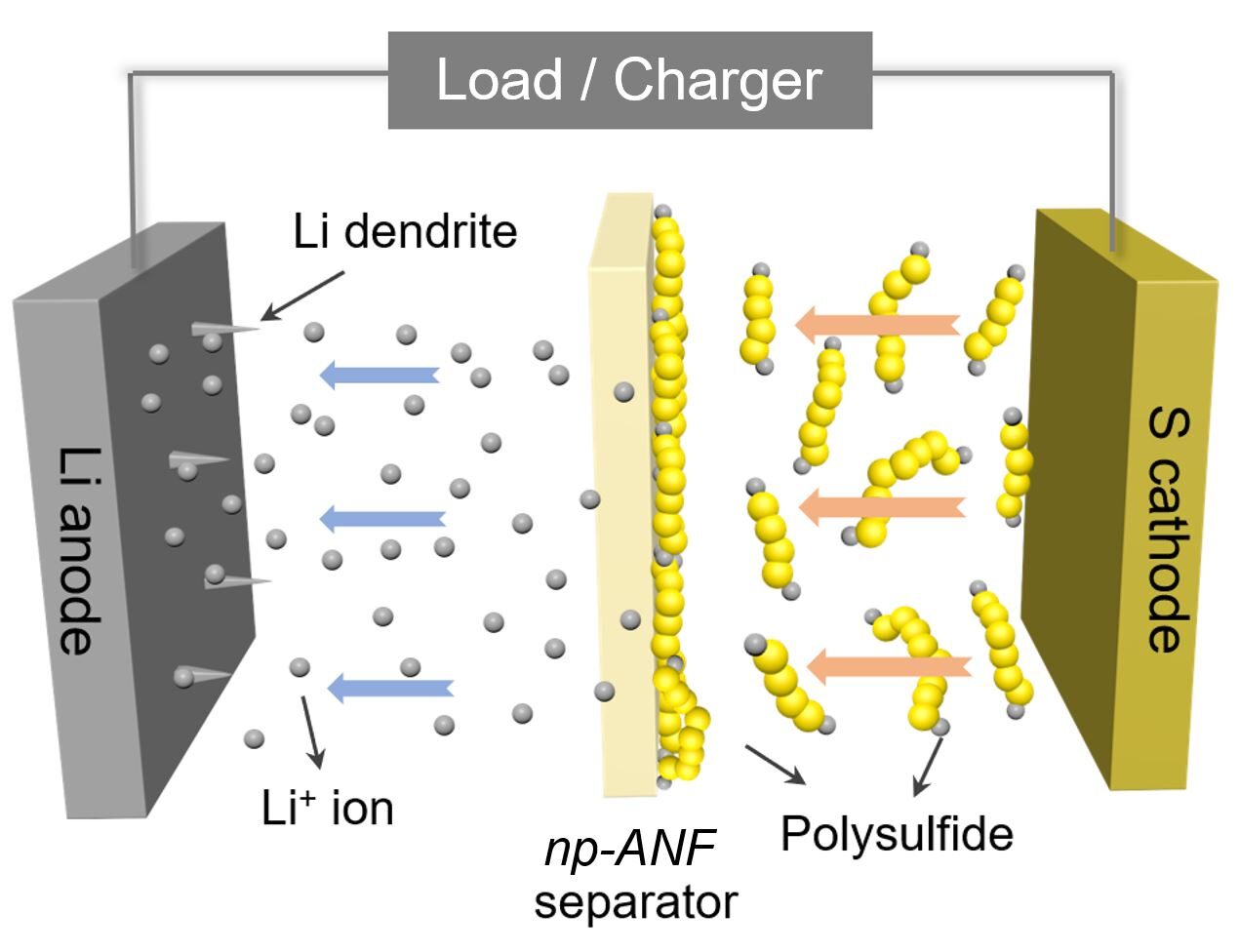

The reason this hasn’t been done before is that Li-S units typically don’t meet recharge standards. That’s because lithium and sulphur molecules attach themselves to the lithium, which reduces battery capacity. The University of Michigan researchers have created a new membrane, consisting of aramid nanofibers made from recycled Kevlar, that could see EV batteries meet the 1,000-recharge cycle needed to actually go into use.

This is quite a technical process, of course. Nicholas Kotov, the Irving Langmuir Distinguished University Professor of Chemical Sciences and Engineering, said, “Biomimetic engineering of these batteries integrated two scales—molecular and nanoscale. For the first time, we integrated ionic selectivity of cell membranes and toughness of cartilage. Our integrated system approach enabled us to address the overarching challenges of lithium-sulfur batteries.”

Boiled down to its most basic form, the aramid nanofibers membrane blocks these lithium and sulphur attachments, by repelling lithium polysulfide ions that might drop EV battery capacity. Through the magic of science, yes? The battery tech may even be ready for production — the university has patented the new membrane and Kotov is working on bringing it to market.

Source: University of Michigan