There is a shortage of readily available semiconductors on planet Earth at the moment, in case you haven’t been paying attention, and it’s just possible that this is a problem that isn’t going away any time soon.

The problem, as you might have guessed, started with the pandemic. People stayed at home, tech sales (including motor vehicles) dropped, and manufacturers cancelled orders for semiconductor products. Then matters eased and orders picked up again, but getting semiconductor production back to its previous levels has proved a little difficult.

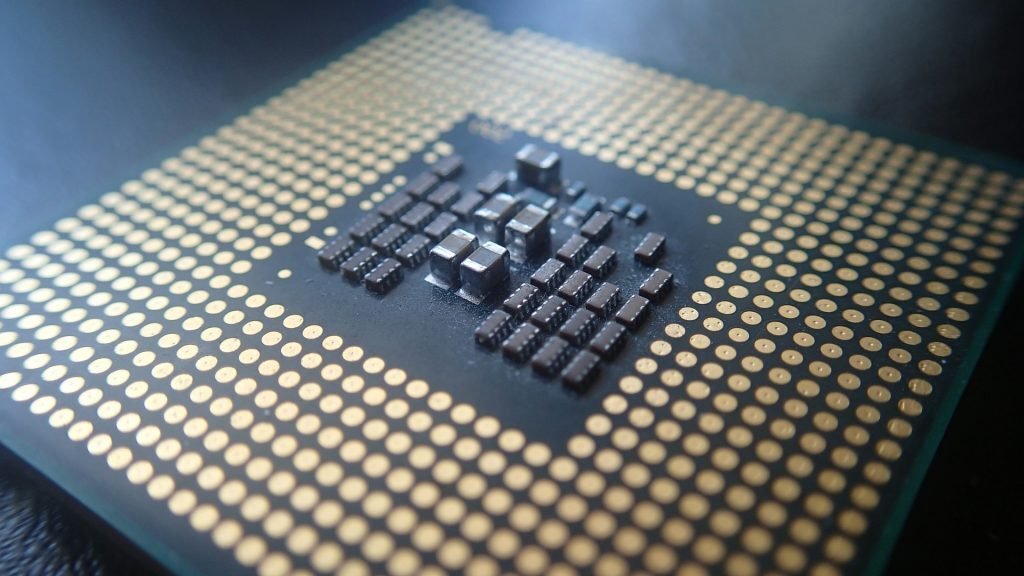

Search for semiconductors

Deloitte’s Chris Richard, who works on the company’s supply chain and network operations, spoke to Ars Technica, explained, “There seems to be a broad consensus that it [semiconductor availability] will stabilize by the end of the year. But if I go back to 2008 and the financial crisis, it was a couple years after the rebound started before everything smoothed out again.”

Manufacturers are ramping up production, but most factories are already running at more than 90% capacity. There’s very little headroom to increase production in most cases, and in the auto manufacturing sector in particular, the chips used are created using older production methods. And, while motor vehicles already use large amounts of chips, the advent of electric cars has only increased the demand-per-vehicle — EVs, obviously, use more electronics. That’s how they work.

And it’s also difficult to repurpose factories to create the hardware needed. It can take up to 26 weeks to produce a chip from start to finish, and vetting new chips from a new factory can take between three to six months. All this means that, while the industry is currently recovering, it’s unlikely to be back to normal before the end of this year. Expect the shortage to continue into 2022.

Source: Ars Technica