The first thing that Stoffel van Wyk appreciated about his new Dyson hairdryer is how quiet it is. These days, he says: “I can have a discussion with my client over the sound of the hairdryer.” Van Wyk has been a hairdresser for 25 years.

“I’ve lost a bit of my hearing because of the constant droning of hairdryers. This is far less intrusive,” he says from his Sandton salon, Urban Sass.

The creator of the Dyson Supersonic Hairdryer, Sir James Dyson, is arguably the UK’s greatest modern-day inventor, having worked for decades to reinvent household objects such as the lowly vacuum cleaner.

When the technology firm named after him announced that it would manufacture a hairdryer, the public responded with huge derision, especially after the cost of the device was announced. It retails for R6,000 in SA.

But the firm has carved a niche for itself making high-end home gadgets that are exceptional.

Take the vacuum cleaner, which traditionally used a bag to catch dust. In 1978, Dyson was frustrated when a cleaner got clogged. He took it apart, realised the bag was the problem and set about making a better cleaner using an industrial cyclone that he had created to separate paint from air. He figured he could do the same with dust.

Take the vacuum cleaner, which traditionally used a bag to catch dust. In 1978, Dyson was frustrated when a cleaner got clogged. He took it apart, realised the bag was the problem and set about making a better cleaner using an industrial cyclone that he had created to separate paint from air. He figured he could do the same with dust.

It took him five years and 5,127 prototypes to invent the world’s first bagless vacuum cleaner. The first models, dubbed G-Force, were sold in Japan for a hefty $2,000 but were a hit.

He took those profits and formed his company in 1991. It now employs more than 12,000 people around the world.

Dyson has a long list of patents and accolades to his name, including a knighthood.

He then turned his inventor expertise to hand dryers in public bathrooms. These were launched in 2006 and prompted even more outrage from the UK public. But these touch-less hand dryers, called Airblade, are really good at drying your hands, and are hygienic in a way no other bathroom option is — and they don’t waste paper towels.

Sure, Dyson’s product choices may seem bizarre. But they have all helped solve problems in the household.

His take on fans is no exception. Instead of using fan blades, the Dyson Air Multiplier (launched in 2009) forces air through an internal system and over an airline wing-shaped surface. It’s a sci-fi-looking device with a smooth flow of air, and with later models — heated air (2011) — from a machine that makes very little noise and looks like it’s part of the International Space Station.

All these products were inspired by the original cyclone technology that Dyson invented in vacuum cleaners, with some impressive upgrades.

This brought Dyson to the hairdryer.

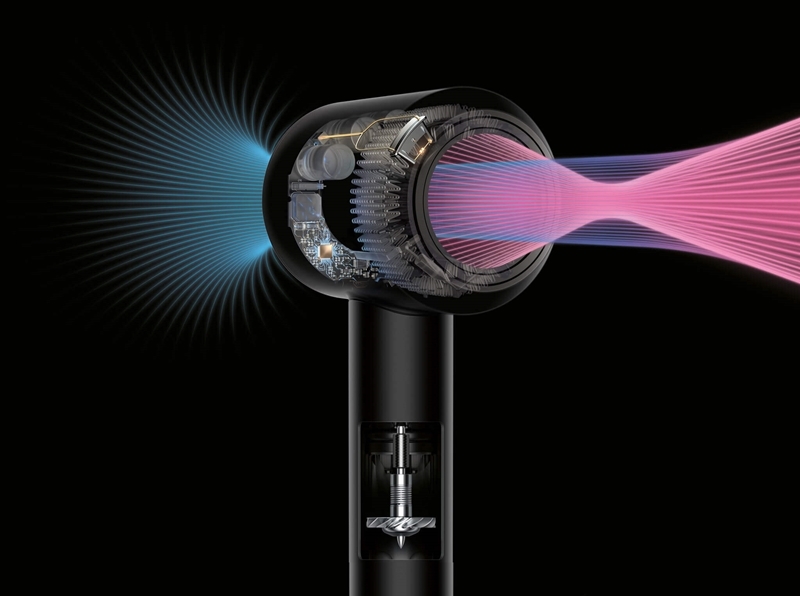

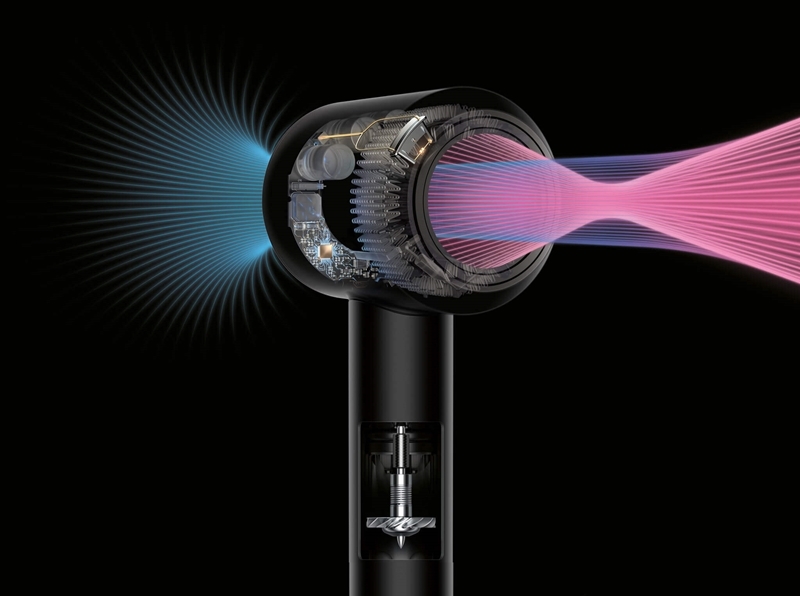

With no moving fan parts, the Dyson Supersonic Hairdryer is another gadget straight out of a sci-fi movie.

Dyson “has a passion for digital motors”, says Brett Coulton, a design engineer at the company.

“He’s been making them for 18 years.”

The engine that powers the hairdryer is, frankly, amazing. Conventional motors are too big for what Dyson had in mind, for a device that is small and compact. Dyson had to make the engine smaller but also more powerful than anything used in hairdryers before.

“We have to spin this little baby at five times faster than a Formula One car,” says Coulton, who worked on the hairdryer. “It spins at 110,000 revolutions per minute.”

The engineering challenges alone were significant, he says. “To get all of that to work in the hairdryer is challenging. With this high-powered, super-fast motor, you also need to make it quiet.”

The engine that drives the airflow is in the handle, making it more comfortable to hold. It uses technology from the Air Multiplier to switch from hot to cold — but it does this without noise and without overheating.

All of this is the reason for Van Wyk’s enthusiasm. The improvement over previous hairdryers is huge, he says.

“Because the motor is in the handle, it’s far less top-heavy than old-fashioned hairdryers. Also, the supersonic motor makes it hardier and its clips are magnetic so the nozzles and the defusers don’t heat up and fall off,” says Van Wyk, who was one of the curators of industry body Intercoiffure Mondial’s hair style collection.

The hairdryer was four to five years in the making, says Coulton. “Just this product in itself cost £50m in investment, had 100 engineers working on it and has been through 600-odd prototypes.”

Dyson spends £7m a week on research & development, says Coulton. “[He] takes a big chunk of the profits and reinvests that into research & development.”

In spite of the huge price tag, retailer Hirsch’s sells 60-80 hairdryers every month, says founder Allan Hirsch.

“It is the most expensive and best-selling hairdryer we’ve got. And we’ve never had a complaint,” he says.

“It’s really efficient and I believe — and I am not saying this as a salesman — it’s worth the investment.”

As Van Wyk says: “It’s a no-fuss tool. It will last 20 times longer than a normal hairdryer.”

And it doesn’t stop there. Dyson’s latest beauty product was unveiled in 2018: a $550 hair iron that draws on the principles of aerospace physics to heat hair without burning it. The iron took six years and $31m to develop.

So what’s next for the inventor?

The company says it will produce its own electric car, at a cost of $2.7bn.

Unsurprisingly, it hopes the car will compete with prestige electric cars like the Tesla and Jaguar’s I-Pace, rather than cheaper models such as the Kia e-Niro and the Nissan Leaf.

The car, which is expected to operate in a radically different way, will be manufactured in Singapore and will launch in 2021.

This column first appeared on Financial Mail