Thousands of years ago, the blacksmith led a technological leap in sub-Saharan Africa. West Africa’s Nok culture, for example, switched from using stone tools to iron around 1500BC. Imagine an innovative artisan like this re-emerging in the 21st century equipped with digital technologies.

This is not Wakanda science fiction. It is the story of a real promise that 3D printing holds for an industrial revolution on the African continent.

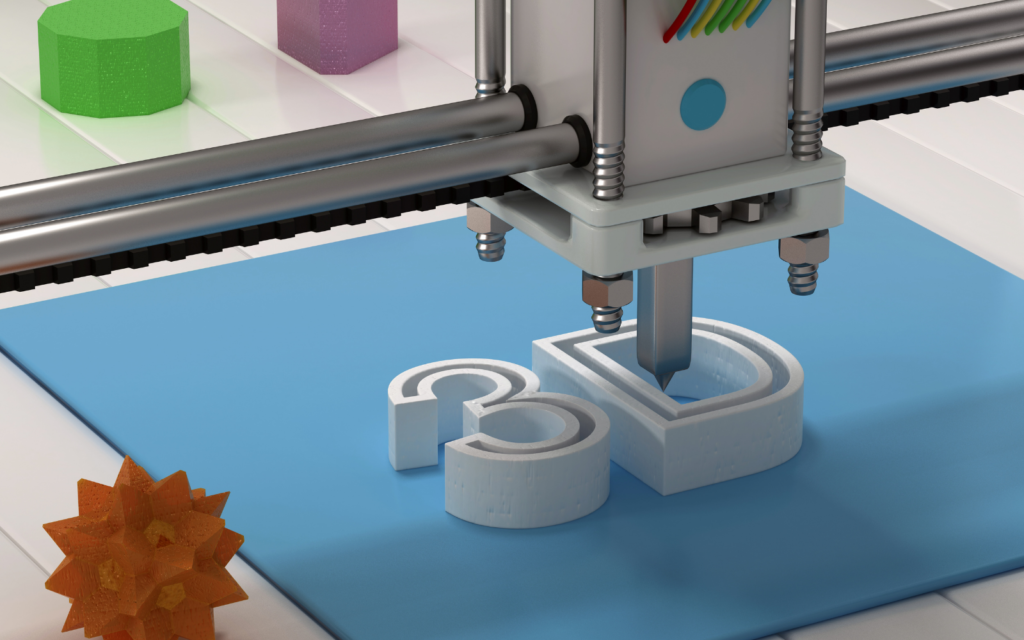

3D printing, also known as additive manufacturing, is a fabrication process in which a three-dimensional object is built (printed) by adding layer upon layer of materials to a series of shapes. The material can be metal, alloys, plastics or concrete. The market size of 3D printing was valued at US$13.78 billion in 2020, and is expected to grow at an annual rate of 21% to a value of US$62.79 billion in 2028.

Not only is it a different way of physically making objects, 3D printing also changes the picture of who can participate in industry – and succeed.

3D printing is an excellent match for smaller operators because it does not require huge capital investment. It is also the best fit for “newcomers” while established operators are locked in the old manufacturing method. The new technology is a great opportunity for developing countries to leapfrog over developed countries.

In a recent paper, we reviewed the evolution of 3D printing technologies, their disruptive impact on traditional supply chains and the global expansion of the 3D printing market.

We show that conditions in the African context are favourable for technological leapfrogging, and propose that universities, industries and government can work together to support this, giving small and medium enterprises a key role.

We illustrate our argument using South Africa and Kenya as examples.

Technological leapfrogging

Technological leapfrogging is related to technology lock-in.

Lock-in happens when an established technology continues to dominate the market even after the arrival of a new and superior technology. The older technology remains successful not because it’s better but because it got the advantages of an early lead in the market.

In developed countries, where the older technology has taken hold, it’s difficult for new, radical technologies to get a start. Too much has already been invested in the old ways.

But it’s different in developing countries. Less has been invested in older technologies. And almost everyone is starting from the same point; the the cell phone is an example.

For a long time, the African continent has lagged behind the rest of the world in manufacturing. A recent report indicates that while Africa is home to 17% of the world’s population, it accounts for only 2% of global manufacturing value added. 3D printing presents an opportunity to revive this sector through technological leapfrogging.

African countries meet the four key conditions highlighted by scholars for technological leapfrogging:

- There must be a large difference between the wage costs of the leading nation and potential challengers.

- The new technology must appear initially unproductive and less profitable relative to the old.

- Experience in the old technology must be less useful and less transferable to the new technology.

- The new technology must, in the long run, improve productivity and efficiency.

To take the first condition, the wage cost of an average African country is a small fraction of the wage cost in a developed country. For example, according to the latest estimates, the average annual income in Nigeria is US$2,000, compared with US$64,530 for the United States.

3D printing is initially unproductive because of lower initial rates of adoption. This means a smaller market and limited profit opportunities.

Looking at the third condition, 3D printing is not an incremental improvement on what went before, so experience in the old technology does not count for much.

On the fourth condition, one of the strongest arguments for 3D printing is that it flips the dominant logic of traditional manufacturing: scale economies. Big multinational manufacturing corporations invest heavily in machinery, logistics and other material and human resources for mass production. They make big profits only if they sell enough units. The more they sell, the bigger their profit margins.

3D printing doesn’t need centralised high-volume production and large inventory stocking. Suddenly, it pays to produce fewer units. There is no need for heavy investment in manufacturing plants, because 3D printers come in various smaller sizes and at lower costs. There is now a growing market for budget and do-it-yourself 3D printers that cost less than US$200.

Smaller and more sustainable

All this shifts the advantage in favour of micro, small, and medium scale enterprises.

Firstly, it offers greater reward for creativity and ingenuity. Like the African blacksmith of yore, additive manufacturers can design customised, higher value products in response to specific demands and requirements.

The proximity of 3D printing shops to customers is another advantage as it reduces logistics costs and supply chain challenges.

Sustainability is another benefit: the process produces only what is needed. It can reuse waste material.

Micro and small-scale 3D printing shops can offer work and income opportunities for households.

University, industry and government

Our study proposes a way for the university, industry and government sectors on the African continent to work together to harness the opportunities offered by 3D printing. These domains – producing knowledge, producing goods and regulating economic relations – have tended to be disconnected. Instead, we argue that greater integration can encourage innovation.

We give examples from South Africa and Kenya to illustrate the challenges and opportunities.

In South Africa, universities are leading the drive to provide training and retraining programmes for engineers, technologists and other professionals involved in 3D printing. Much more needs to be done to develop new curricula, research and programmes in additive manufacturing.

Kenyan universities are at an earlier stage, focusing on convening networking and knowledge exchange events.

In the government sector, South Africa has the most detailed policy document of any African country on 3D printing. The country’s 3D printing strategy is being led through the Ministry of Science and Technology, and through agencies such as the Council for Scientific and Industrial Research and Technology Innovation Agency. In the industry sector, South Africa’s Rapid Product Development Association works closely with the government to organise conferences, workshops and community engagement activities.

The results so far

The South African 3D printing industry has had considerable success in recent years, driven by a growing community of enthusiasts and designers.

Small enterprises and startups are making inroads in areas such as 3D printing of cell phone accessories, car accessories, and jewellery. In 2014, South African doctors used 3D-printed titanium bones to perform a jaw-bone transplant surgery, the second in the world. There are also recent applications of 3D printing in housing.

The three spheres need to do more work in research investment, policy interventions and strategic public procurement. And they need to cross boundaries. Universities can commercialise and contribute to policies. Industry can invest in research and influence policies. Governments can play in the market and in knowledge production.

This article first appeared on The Conversation.