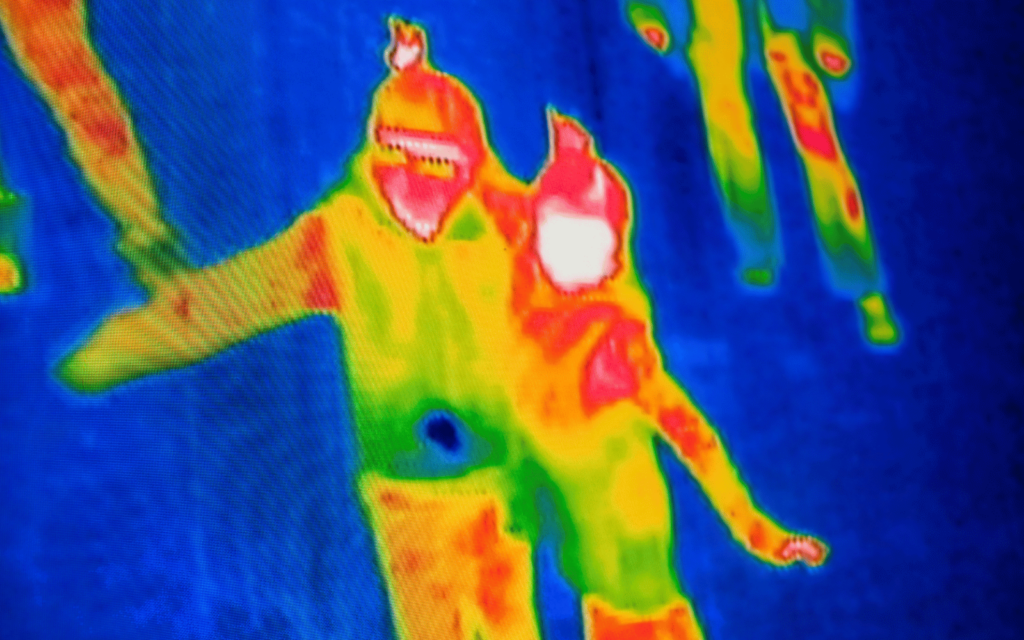

Like something out of a spy movie, thermal cameras make it possible to “see” heat by converting infrared radiation into an image. They can detect infrared light given off by animals, vehicles, electrical equipment and even people – leading to specialised applications in a number of industries.

Despite these applications, thermal imaging technology remains too expensive to be used in many consumer products such as self-driving cars or smartphones.

Our team at Flinders University has been working hard to turn this technology into something we can all use, and not just something we see in spy movies. We’ve developed a low-cost thermal imaging lens that could be scaled up and brought into the lives of everyday people. Our findings are published in the journal Advanced Optical Materials.

Thermal imaging across industries

Thermal imaging has obvious applications in surveillance and security, given its ability to detect the heat signature of people. It’s not surprising defence forces all over the world use this technology – including in Australia.

In medicine, it can be used to detect tissues of a higher temperature. This means thermal cameras are useful in the non-invasive detection of tumours, which run at a higher metabolism (and temperature) than healthy tissue.

Thermal imaging even plays a crucial role in space exploration. For instance, it can be used to image distant stars, galaxies and planets, because infrared light can penetrate dust clouds much better than visible light. NASA’s James Webb Space Telescope also takes infrared images – and its ability to see far “redder” wavelengths is opening up new corners of the universe for us.

Read More: Canon’s new EOS R100 mirrorless camera is their most affordable one to date

Addressing the high-cost conundrum

Above are just some examples in a long list of the specialised applications of thermal imaging. Yet this technology could have many more potential uses if it wasn’t so expensive to produce.

The high cost comes, in part, from the materials used to produce the camera lenses. These lenses need to have special properties that allow them to be used with infrared radiation in a way standard lenses can’t.

Most glasses and plastics will absorb infrared radiation, so expensive materials such as germanium or zinc selenide must be used. Both materials can be difficult to manufacture and maintain; germanium is a critical element in short supply, and zinc selenide contains toxic elements.

Our team wanted to address the lens challenge head-on. We developed a new polymer made from the low-cost and abundant building blocks of sulfur and cyclopentadiene (an organic compound that takes the form of a colourless liquid).

The cost of the raw materials for the lens we’ve developed is less than one cent per lens. In comparison, some germanium lenses can cost thousands of dollars.

This new sulfur-based lens can also be moulded and cast into a variety of complex shapes through common techniques used in the plastics industry. These techniques are simpler and less energy-intensive than those used to create conventional infrared lenses – further reducing the cost and making the polymer more scalable.

The key to developing this material was figuring out how to use cyclopentadiene as a gas for the reaction with sulfur. By doing this, we could precisely control the composition of the resulting polymer – leading to a lens with enhanced capabilities for thermal imaging.

Despite being completely opaque to visible light, the polymer has the highest long-wave infrared transmission of any plastic that has been reported – which means it can be used with a thermal imaging camera.

Possible applications

The development of this material opens doors to many new thermal imaging applications that weren’t possible before.

Self-driving cars could use this technology to detect pedestrians or vehicles – even in low light or fog. Or it could be used in agriculture to monitor irrigation and crop health. Importantly, it would be affordable for farmers.

The new lens is also lightweight, which is helpful for aerial imaging by drone.

Finally, it could be integrated into consumer electronics such as smartphones, computers and home automation systems, to name a few. This would enable users to take thermal images or videos at any time from their phone. It could even be used to create next-generation smoke alarms.

The advances developed in this new study have significantly reduced the barrier to using thermal imaging – and may help revolutionise how it’s used in our everyday lives.

- is a PhD Candidate, College of Science and Engineering, Flinders University

- is a Matthew Flinders Professor of Chemistry, Flinders University

- This article first appeared on The Conversation