It is unlike any 5G tower you’ve seen before. And unlikely to see in the flesh yourself. This is perhaps because it’s underground, very far underground. In a coal mine. In China.

This is the cutting edge of technology and is using superfast wireless connectivity in an interesting new way. Made by Huawei, this 5G system aims to show how this super-fast wireless communications network can be used in the most unexpected of places: in a mine.

Digging deeper into 5G

This is an interesting test case for 5G technology and the artificial intelligence (AI) applications it makes possible. And it demonstrates how safety can be implemented using these sophisticated tools.

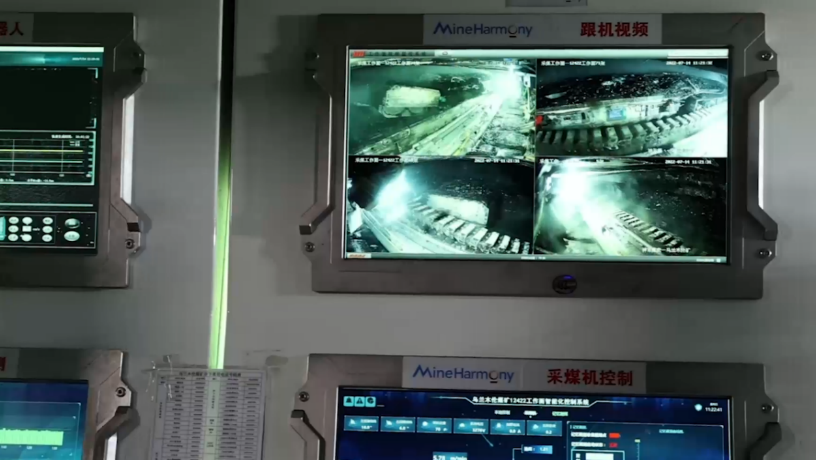

Faster connections mean better quality video from cameras on remote mining equipment. They also provide better data and do this in real time. These ultra-high bandwidth 5G networks can stream hundreds of channels of HD video, of up to 1 Gbit/s. In real-time. Underground.

It helps that 5G has low latency, giving quicker responsiveness to remotely controlled machines. This means operators can make changes faster, often in real-time.

There are also algorithms to detect potential hazards during the dangerous tunnelling step of the process, which accounts for 40% of coal mine accidents in China. As much as 50% of these are attributed to human error. AI algorithms, therefore, monitor the video feed to check that all the safety steps are properly followed and issue real-time alerts if they aren’t.

Another underground application is in the transportation of the coal via giant belt conveyors that can stretch 20kms. As many as 20 inspectors check this system, but it can be more efficiently done by algorithms which detect anomalies in the moving belt. If only Eskom had that.

Safety first

On top of the connectivity, Huawei has tried to solve the disconnect between the vast number of different devices and operating systems they use. There are over 1,000 types of underground mining equipment, of which can’t be remotely controlled.

To solve this, Huawei’s Mine Team, China Energy and 30 partners developed MineHarmony, the first Internet of Things (IoT) operating system for the mining sector.

Built in three months, MineHarmony aims to unify the 10 types of operating systems, 500 types of interface protocols and other protocols.